Everything You Need to Know about Drones for Your Solar Farm

Solar Farm Inspection, Efficiency, and More

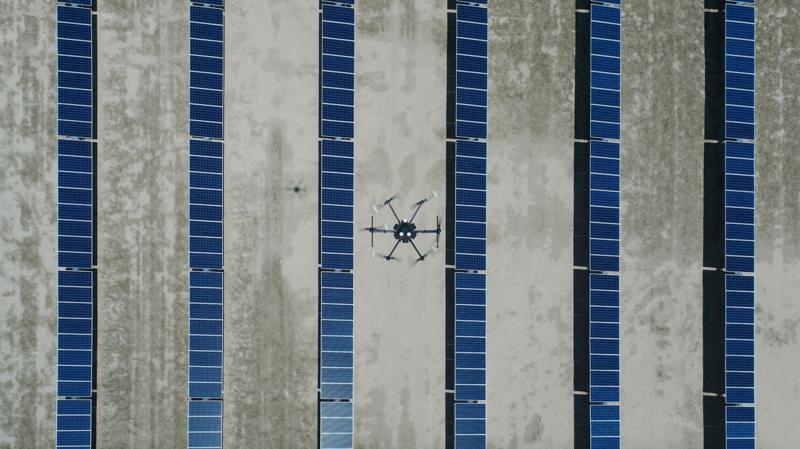

A drone’s capacity to cover vast distances and provide high-resolution aerial images has allowed many companies to optimize their efficiency when completing dangerous or time-consuming tasks. Drones have provided solar farm managers with accurate data via new technological developments, such as thermal sensors, ensuring that routine operations are conducted more efficiently.

Companies across the Energy Industry, are combining cutting edge technology with drones to increase the efficiency of their energy plant operations, with drones playing a critical role in their quest to provide reliable and affordable energy to their customers.

The Solar Energy Industry: Growing with Further Needs for Optimization

In response to the rising concerns about climate change and carbon emissions, many countries around the world have increased their investments in renewable energy projects. Solar power has been a preferred solution when considering the many renewable energy sources. Over the past decade (2009-2019), investments in solar energy reached USD $1.3 trillion worldwide, accounting for half of the total assets contributed to the growth of renewable energy.[1]

One of the reasons for the large adoption of solar solutions has been the decrease in the total cost for installation. Solar KW, for example, has witnessed their installation costs decrease by about 73%, from USD $4,621 in 2010 to USD $1,210 in 2019.[2] The goal now is to continue making solar power affordable worldwide. To achieve this, solar energy managers must optimize operations and create value throughout the entire energy generation process.

Challenges of Solar Farm Inspections

To fulfill energy demands, solar energy companies must install thousands of solar panels distributed across large, typically highly irradiated areas. Essentially, a solar farm requires around 2,500 acres to supply energy to 100,000 households.[3]

Traditional solar field assessments consist of inspecting each panel with handheld thermal imagers to check for defective cells or cables. During this process, personnel have to manually keep track of the faulty panels’ locations to perform maintenance afterward. Given the dimensions of most solar farms, this method of inspecting is inefficient and results in a heavier, and sometimes hazardous, workload to maintenance and operations teams.

The integration of drone technology has undoubtedly improved the efficiency and accuracy of the inspection process. Drones like the DJI Matrice 210 RTK V2, equipped with XT2 thermal payloads, can survey large areas within a solar farm, collecting high-resolution RGB and thermal images during a single flight.

Drones are continuously being used on solar farms to improve inspection operations, especially areas that are highly irradiated and create a host of issues for on-site teams. The use of drones allows solar farm teams to cut inspection time by 70%, a significant reduction when compared to traditional methods.

Performing Drone Inspections of Solar Farms

Inspecting solar farms using drones is not a simple flight task. The process involves detailed planning and a thorough understanding of the area to be inspected. There are multiple steps required to conduct a successful inspection.

Solar Farm Assessment

First, the inspection team needs to confirm the dimensions of the solar farm before they can prepare an effective plan. Every inspection has its own characteristics, but there are certain common aspects to be mindful of during the assessment stage. This includes the area of the farm, the number of installed panels, and the power production capacity.

Flight Planning

Flight plans are created based on the information collected during the assessment phase and capacity of the inspection team (i.e., available drones and pilots). After evaluating the Ground Sample Distance (GSD) required by the client and the battery capacity of the drones, the max area that can be covered per flight can be confirmed. These flight plans are then imported into the DJI Pilot app, helping prepare drone operators for execution.

Data Collection

By this point, the inspection team should have the necessary information and flight plan to begin operation. Having multiple batteries is recommended, and the inspection team must ensure that the batteries are changed and recharged regularly to optimize workflow. Depending on the solar farm dimensions and the flight plans, inspection teams can usually perform up to 25 flights and collect over 6,500 images per day.

Data Organization & Processing

All collected data should be stored and organized for processing. Photogrammetry software reconstructs RGB Orthomosaics and thermal maps from the images obtained. It also adjusts the positioning using Ground Control Points. After reconstruction and positioning adjustments are set, mapping files can be integrated into a Geography Information System, where maintenance teams can quickly identify anomalies that reflect potential faults.

Benefits of Using Drones for Aerial Inspections

RGB and Thermal Images

Aerial images provide a broader perspective of solar farms and allow maintenance teams to receive valuable information in real-time, like the status of each panel. When analyzing thermal maps, it is easier to identify potential problems by detecting heat anomalies across cells, strings, or panels. Combining thermal and RGB data helps you determine if the heat anomalies are caused by faults found physically on the panel, such as delamination, cracks, dust, or internal issues such as the inability to connect to a panel due to an inverter or cable failure.

Time Efficiency

One of the main reasons for adopting drones for solar panel inspections is increased efficiency in saving time. Juan Francisco Mosqueda, a drone inspection service provider, explains how time is saved using drones. “By using two drone teams, we can inspect around 617 acres in a day,” he said. “The same amount of work would take three or four months if we were to inspect manually.”

The use of aerial images not only contributes to the improved efficiency in detecting flaws, but it also helps tremendously with maintenance. RBG and thermal maps provide precise location data of faults and issues, significantly increasing the accuracy of ground operations and reducing human error.

Historical Data

Keeping records of previous inspections is useful for figuring out the causes behind panel faults. In some cases, issues with solar cells do not justify the replacement of a panel, but it is essential to keep track of them to prevent major failures. To make historical data more valuable, it is recommended to perform an aerial inspection after completing installation and use the resulting data as a baseline for future inspections.

Output Efficiency

Early detection of faulty elements within a solar farm will help to prevent major output deficiencies. The faster a maintenance team can detect possible defects, the quicker they can respond and prevent major system failures. In the end, inspections and maintenance that are effectively conducted translate into protecting the interests of investors and ensuring that the demand for cleaner energy can be met with incredible efficiency.

Drone Applications Continue to Expand

With the emergence of enterprise-focused solutions, various industries now have access to tools that will help them complete tasks much more effectively. Energy inspections usually require thermal images, while mapping solutions are more focused on precision positioning with RTK modules. Operation teams should evaluate the desired outcome of drone inspections and find a suitable solution that matches those needs.

As more companies have begun utilizing drones to improve routine operations, DJI continues to develop enterprise-focused solutions to meet industry demands. The versatility and broad application of drones have introduced a safer and more efficient way of working, foreshadowing a promising future of technology and innovation.

If you operate within the energy industry and are looking to implement drone-based solutions into routine inspections, read more from our energy section here.

Learn more about Incorporating drones in Solar Energy operations in our webinar here.

Subscribe for Similar Content

We'll keep you up to date with more stories about drones in the energy industry and other relevant updates.

Sources:

3 https://greencoast.org/solar-farm-land-requirements/