Facility Inspection

During the daily inspection of pumping units, numerous points require meticulous attention. However, many inspection points are difficult to access and observe. Drones equipped with visible light and thermal cameras can effectively address this challenge by capturing multi-angle videos and photos, which can detect issues such as overheating, oil leaks, loose belts, and bolts. Additionally, drones can help bridge the gap in digital management systems and reduce the manual workload by providing easily stored and trackable inspection data.

Painpoints

Advantages

The structure's complexity, with many blind spots, makes it challenging for inspection teams to conduct thorough inspections.

Close-range, multi-angle inspections effectively address the issue of blind spots and dead corners, enabling the identification of potential problems.

Oil fields are often hazardous and vast, requiring frequent inspections. This results in a significant allocation of human resources to inspection tasks.

Drones can cover large areas, reducing the need for manual labor on foot and ensuring the safety of personnel and production.

Traditional inspection methods cannot be easily digitized, archived, or traced.

Inspection data can be easily stored and tracked over time, leading to improvements in asset management and preventive maintenance efforts.

Oil field operations are subject to stringent regulations and must comply with local, state, and federal standards.

Drone data can be utilized to monitor and ensure operational compliance, as well as to generate supporting documentation and reports for compliance teams.

Solution

Automated Facility Inspection

Reliable and High Performance Inspection

Gas Leak Detection and Thermal Inspection

Portable Quick Assessment Inspection

Automated Facility Inspection

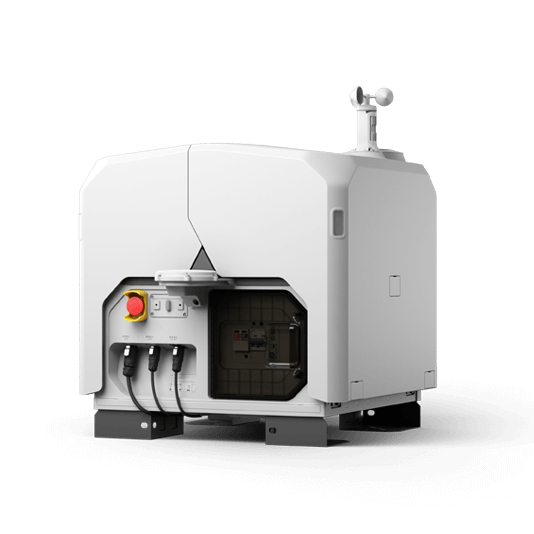

The DJI Dock 3 enables effortless automation of recurring inspection tasks. Schedule an inspection task, and the DJI Dock 3 will automatically collect data and upload the results to DJI FlightHub 2 for further analysis and processing.

It is lightweight and portable, making it easy to install and relocate as needed.

Plan, schedule, and manage your inspection missions remotely from a centralized cloud platform with DJI FlightHub 2.

Rated IP56 to withstand harsh environments.

An operating radius of 10 km allows coverage of large facilities with just a few docking stations.

Ensure precise inspections with the built-in RTK system.

Drone Platform

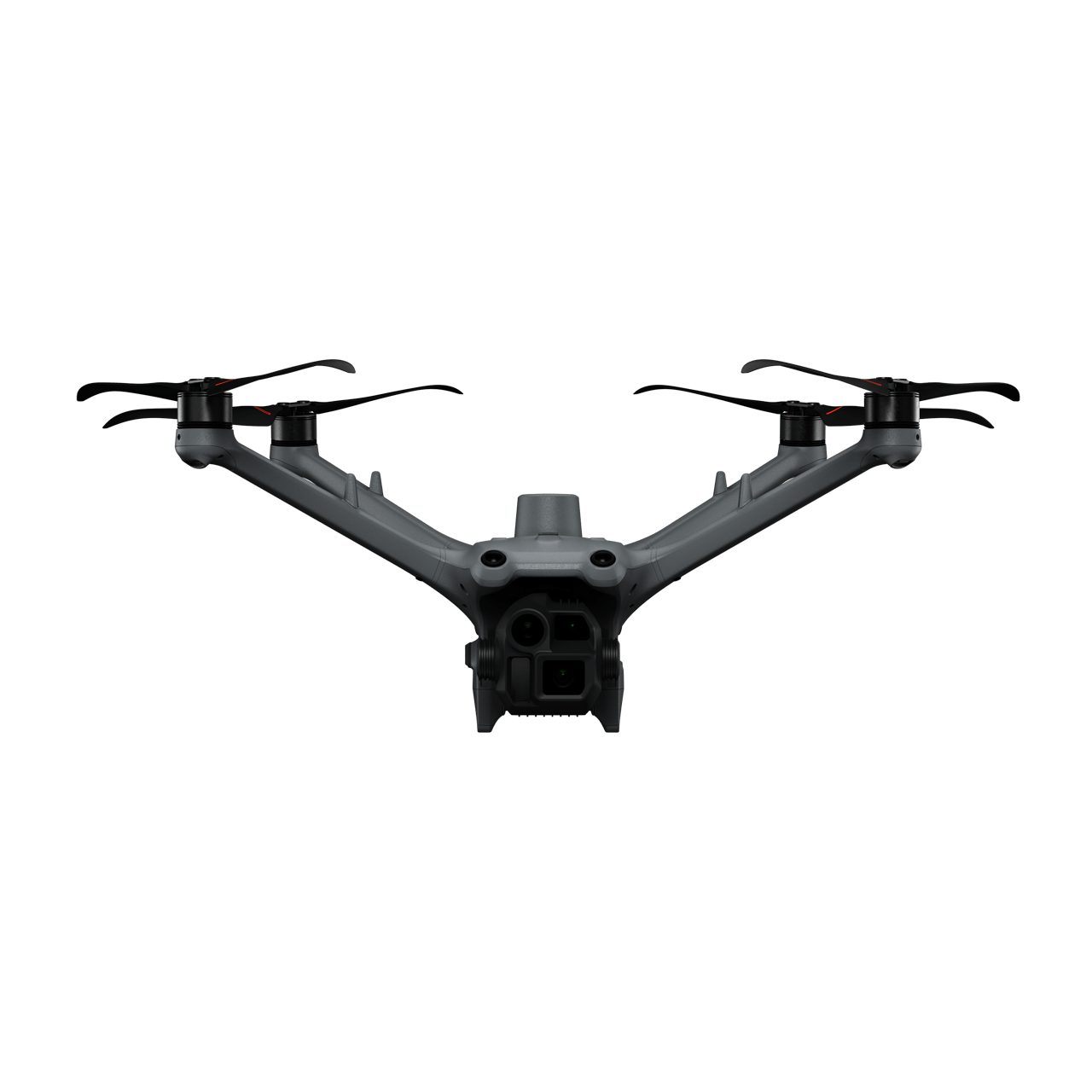

DJI Matrice 4D

... Open

Weight: 1850 g

Max Flight Time: 54 minutes

Environment Adaptability: IP55 rating, max takeoff altitude 6500 m, max wind speed resistance 12 m/s

Sensing System: Omnidirectional binocular vision system, supplemented with a 3D infrared sensor at the bottom of the aircraft

Mechanical Shutter Speed: 2-1/2000 s, minimum photo interval 0.5 s

Wide-Angle Camera: 4/3-inch CMOS, 20MP effective pixels

Medium Tele Camera: 1/1.3-inch CMOS, 48MP effective pixels

Telephoto Camera: 1/1.5-inch CMOS, 48MP effective pixels

Laser Rangefinding: 1800m measurement range (1 Hz) @20% reflectivity target

Max Flight Time: 54 minutes

Environment Adaptability: IP55 rating, max takeoff altitude 6500 m, max wind speed resistance 12 m/s

Sensing System: Omnidirectional binocular vision system, supplemented with a 3D infrared sensor at the bottom of the aircraft

Mechanical Shutter Speed: 2-1/2000 s, minimum photo interval 0.5 s

Wide-Angle Camera: 4/3-inch CMOS, 20MP effective pixels

Medium Tele Camera: 1/1.3-inch CMOS, 48MP effective pixels

Telephoto Camera: 1/1.5-inch CMOS, 48MP effective pixels

Laser Rangefinding: 1800m measurement range (1 Hz) @20% reflectivity target

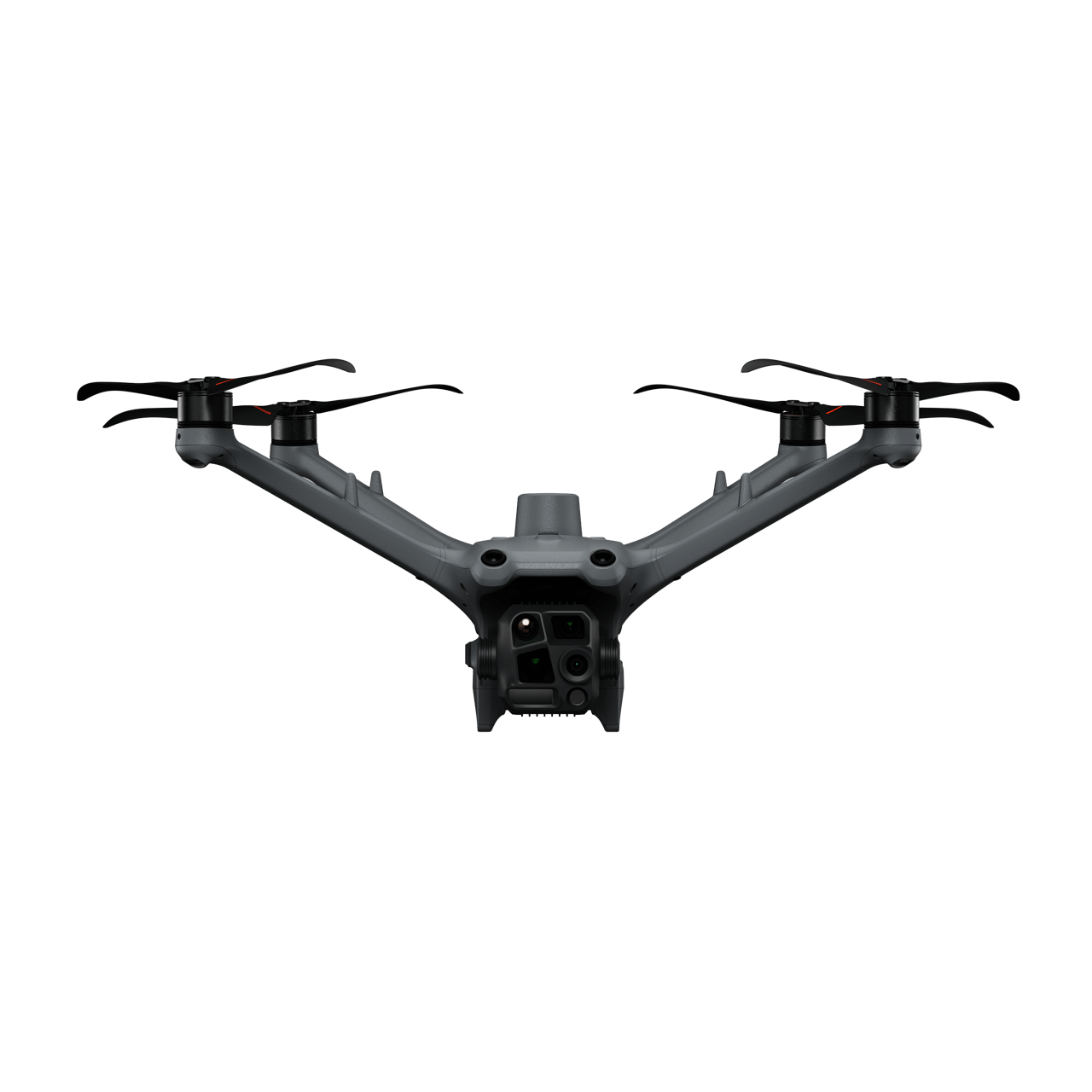

DJI Matrice 4TD

... Open

Weight: 1850 g

Max Flight Time: 54 minutes

Environment Adaptability: IP55 rating, max takeoff altitude 6500 m, max wind speed resistance 12 m/s

Sensing System: Omnidirectional binocular vision system, supplemented with a 3D infrared sensor at the bottom of the aircraft

Wide-Angle Camera: 1/1.3-inch CMOS, 48MP effective pixels

Medium Tele Camera: 1/1.3-inch CMOS, 48MP effective pixels

Telephoto Camera: 1/1.5-inch CMOS, 48MP effective pixels

Infrared Thermal Camera: 1280 × 1024@30fps (UHR Infrared Image function enabled, Night Scene mode not enabled)

Laser Rangefinding: 1800m measurement range (1 Hz) @20% reflectivity target

Max Flight Time: 54 minutes

Environment Adaptability: IP55 rating, max takeoff altitude 6500 m, max wind speed resistance 12 m/s

Sensing System: Omnidirectional binocular vision system, supplemented with a 3D infrared sensor at the bottom of the aircraft

Wide-Angle Camera: 1/1.3-inch CMOS, 48MP effective pixels

Medium Tele Camera: 1/1.3-inch CMOS, 48MP effective pixels

Telephoto Camera: 1/1.5-inch CMOS, 48MP effective pixels

Infrared Thermal Camera: 1280 × 1024@30fps (UHR Infrared Image function enabled, Night Scene mode not enabled)

Laser Rangefinding: 1800m measurement range (1 Hz) @20% reflectivity target

DJI Dock 3

... Open

Weight: 55 kg (without the drone)

Size: 1760×745×485 mm (L×W×H, dock cover opened)

Environment Adaptability: -30° to 50° C (-22° to 122° F) operating temperature, IP56 rating, maximum operating altitude 4500 m

Max Operating Radius: 10 km

Charging Time: 27 minutes

Security Camera (Internal) Resolution: 1920×1080

Size: 1760×745×485 mm (L×W×H, dock cover opened)

Environment Adaptability: -30° to 50° C (-22° to 122° F) operating temperature, IP56 rating, maximum operating altitude 4500 m

Max Operating Radius: 10 km

Charging Time: 27 minutes

Security Camera (Internal) Resolution: 1920×1080

Payload And Software

Workflow

- Mission Planning:

- Use DJI FlightHub 2 to plan inspection routes based on high-definition 3D models of the facility.

- Or import previously saved inspection flight routes to the DJI FlightHub 2 via the Pilot 2 app using the Live Mission Recording feature. - Data Collection:

- Using DJI FlightHub 2 select the preferred dock and scheduled inspection mission.

- The Matrice 4TD or Matrice 4D will execute the inspection tasks according to the plan, and upload the captured data to DJI FlightHub 2.

- If an abnormaly is detected during the flight, adjust the flight mission with manual controls and live-stream from the command center. - Data Analysis:

- Analyze the images to detect defects or required maintenance work by manually reviewing the data collected. Transfer the data to a third-party sofware to identify equipment defects using model detection.

Reliable and High Performance Inspection

The DJI Matrice 30 Series delivers portability and powerful performance, capable of handling challenging conditions. This solution enables inspection professionals to detect abnormalities with its high-resolution visual and thermal (M30T) sensors, dual-control operations, and precise re-shooting capabilities.

The drone is foldable and portable, allowing for easy transportation to outdoor tasks.

Quick deployment, ready to fly in just 2 minutes.

Cost-effective, featuring an integrated infrared camera for direct temperature measurement operations.

Low-light mode ensures detailed image capture even in dimly lit environments.

Drone Platform

Matrice 30T

... Open

Weight (incl. two batteries): 3770 ± 10 g.

Max Flight Time: 41 min.

Sensing system: Six-directional sensing and positioning.

Environment Adaptability: Max Service Ceiling Above Sea Level (without other payload) 7,000 m (with 1676 propellers); Max Wind Resistance 12 m/s.

Zoom camera: 1/2-inch CMOS, Effective pixels: 48MP.

Max Flight Time: 41 min.

Sensing system: Six-directional sensing and positioning.

Environment Adaptability: Max Service Ceiling Above Sea Level (without other payload) 7,000 m (with 1676 propellers); Max Wind Resistance 12 m/s.

Zoom camera: 1/2-inch CMOS, Effective pixels: 48MP.

Payload And Software

DJI Pilot 2

... Open

Ground control

Workflow

- Mission Planning:

- Using the Live Mission Recording feature, perform a manual inspection flight to generate the baseline flight route for future inspections. - Data Collection:

- Import the generate flight mission into the DJI Pilot 2 app.

- Perform future inspection task with one click by selecting the previously imported flight mission and the drone will collect the same data as the baseline route. - Data Analysis:

- Analyze the images to detect defects or required maintenance work by manually reviewing the data collected. Transfer the data to a third-party sofware to identify equipment defects using model detection.

Gas Leak Detection and Thermal Inspection

The DJI Matrice 400 is a dependable platform with interchangeable payloads tailored to meet the needs of specific tasks. When paired with a third-party gas detector sensor, inspection teams can identify gas leaks that may otherwise go undetected by the human eye.

Equipped with a variety of payloads, it provides operational efficiency and improved inspection capabilities.

Detect and accurately pinpoint leaks in real-time from a safe distance, minimizing risk to personnel and enabling precise repairs.

Longer flight time and extended transmission range allow for covering large areas, identifying leaks and defective equipment more efficiently.

Paired with the Zenmuse H30 Series, it offers high-definition zoom, thermal (H30T) and a laser rangefinder.

Drone Platform

DJI Matrice 400

... Open

Weight: 9740±40 g (with batteries)

Max Takeoff Weight: 15.8 kg

Max Payload: 6 kg

Max Flight Time: 59 minutes

Max Horizontal Speed: 25 m/s

Sensing System: Omnidirectional binocular vision system (surround view provided by full-color fisheye vision sensors), horizontal rotating LiDAR, upper LiDAR, downward 3D infrared range sensor, and six-direction mmWave radar

Environment Adaptability: IP55 rating, max takeoff altitude 7000 m, operating temperature -20° to 50° C (-4° to 122° F)

Compatible with the Zenmuse H30 Series, Zenmuse L2, Zenmuse P1, Zenmuse V1, Zenmuse S1, and third-party payloads.

Max Takeoff Weight: 15.8 kg

Max Payload: 6 kg

Max Flight Time: 59 minutes

Max Horizontal Speed: 25 m/s

Sensing System: Omnidirectional binocular vision system (surround view provided by full-color fisheye vision sensors), horizontal rotating LiDAR, upper LiDAR, downward 3D infrared range sensor, and six-direction mmWave radar

Environment Adaptability: IP55 rating, max takeoff altitude 7000 m, operating temperature -20° to 50° C (-4° to 122° F)

Compatible with the Zenmuse H30 Series, Zenmuse L2, Zenmuse P1, Zenmuse V1, Zenmuse S1, and third-party payloads.

Workflow

- Data Collection:

- Fly the drone manually or use waypoint mission flight on the DJI Pilot 2 app or third-party Payload app.

- If the gas detector senses a leak it will trigger an alert. Capture images and sensor data on the spot to evaluate the situation. - Data Analysis:

- Review the gas sensor and visual inspection data to detect defects or required maintenance work.

Portable Quick Assessment Inspection

The DJI Matrice 4E / 4T drones are compact and adept at navigating through relatively narrow spaces between equipment. Equipped with high-definition visible light and infrared cameras (M4T), they are the perfect solution for swiftly getting eyes in the sky to rapidly inspect equipment or structures at a facility.

Their compact size enables navigation through narrow spaces, meeting safety regulations and providing optimal shooting angles.

Quick deployment and user-friendly operation allow for rapid assessments of facility infrastructure and equipment.

High-resolution visual and thermal sensors capture quality images, identifying defects that may easily be overlooked by the naked eye.

Drone Platform

DJI Matrice 4T

... Open

Weight: 1219 g (with propellers)

Max Flight Time (without wind): 49 minutes

Environment Adaptability: Max takeoff altitude 6000 m, max wind speed resistance 12 m/s

Sensing System: Omnidirectional binocular vision system, supplemented with a 3D infrared sensor at the bottom of the aircraft

Wide-Angle Camera: 1/1.3-inch CMOS, 48MP effective pixels (Matrice 4T)

Medium Tele Camera: 1/1.3-inch CMOS, 48MP effective pixels

Telephoto Camera: 1/1.5-inch CMOS, 48MP effective pixels

Infrared Thermal Camera: 1280 × 1024@30fps (Super Resolution enabled, Night Mode not activated)

Laser Rangefinding: 1800m measurement range (1 Hz) @20% reflectivity target

Max Flight Time (without wind): 49 minutes

Environment Adaptability: Max takeoff altitude 6000 m, max wind speed resistance 12 m/s

Sensing System: Omnidirectional binocular vision system, supplemented with a 3D infrared sensor at the bottom of the aircraft

Wide-Angle Camera: 1/1.3-inch CMOS, 48MP effective pixels (Matrice 4T)

Medium Tele Camera: 1/1.3-inch CMOS, 48MP effective pixels

Telephoto Camera: 1/1.5-inch CMOS, 48MP effective pixels

Infrared Thermal Camera: 1280 × 1024@30fps (Super Resolution enabled, Night Mode not activated)

Laser Rangefinding: 1800m measurement range (1 Hz) @20% reflectivity target

DJI Matrice 4E

... Open

Weight: 1219 g (with propellers)

Max Flight Time (without wind): 49 minutes

Environment Adaptability: Max takeoff altitude 6000 m, max wind speed resistance 12 m/s

Sensing System: Omnidirectional binocular vision system, supplemented with a 3D infrared sensor at the bottom of the aircraft

Mechanical Shutter Speed: 2-1/2000 s, minimum photo interval 0.5 s

Wide-Angle Camera: 4/3-inch CMOS, 20MP effective pixels

Medium Tele Camera: 1/1.3-inch CMOS, 48MP effective pixels

Telephoto Camera: 1/1.5-inch CMOS, 48MP effective pixels

Laser Rangefinding: 1800m measurement range (1 Hz) @20% reflectivity target

Max Flight Time (without wind): 49 minutes

Environment Adaptability: Max takeoff altitude 6000 m, max wind speed resistance 12 m/s

Sensing System: Omnidirectional binocular vision system, supplemented with a 3D infrared sensor at the bottom of the aircraft

Mechanical Shutter Speed: 2-1/2000 s, minimum photo interval 0.5 s

Wide-Angle Camera: 4/3-inch CMOS, 20MP effective pixels

Medium Tele Camera: 1/1.3-inch CMOS, 48MP effective pixels

Telephoto Camera: 1/1.5-inch CMOS, 48MP effective pixels

Laser Rangefinding: 1800m measurement range (1 Hz) @20% reflectivity target

Payload And Software

DJI Pilot 2

... Open

Ground control

DJI Thermal Analysis Tool 3

... Open

By identifying the temperature information of critical areas of the target, the software can be used to analyze objects across many industrial applications.

Workflow

- Data Collection:

- Manually fly the Matrice 4E / 4T drone covering narrow spaces and getting closer looks at key components using the zoom capabilitites. - Data Analysis:

- Import the images to DJI Thermal Analysis Tool to analyze the inspection results manually or import to a third-party software to identify equipment defects using model detection.