Photovoltaic Power Plant

Drones can precisely identify and locate defects in solar farms by utilizing high-definition visible light and thermal imaging. This facilitates early fault detection and preventive maintenance, thereby improving the quality and efficiency of photovoltaic power stations.

Painpoints

Advantages

The scale of photovoltaic projects is expanding rapidly, making it challenging to allocate operation and maintenance personnel promptly.

Deploy resources more efficiently and minimize personnel risk by reducing time spent in the field and pinpointing faulty components with accuracy.

The process of collecting and analyzing data from solar inspections can be laborious and complex.

Integrate drone data collection with advanced detection algorithms to streamline fault identification and enhance inspection efficiency.

The efficiency of photovoltaic panels can be significantly affected and diminished by exposure to factors such as dust, dirt, or other contaminants.

Merge visual and thermal data to accurately assess the condition of components and make well-informed maintenance decisions.

Solution

Automated Solar Farm Inspection

High Performance Inspection

Portable Thermal Inspection Solution

Multipurpose Drone Inspection

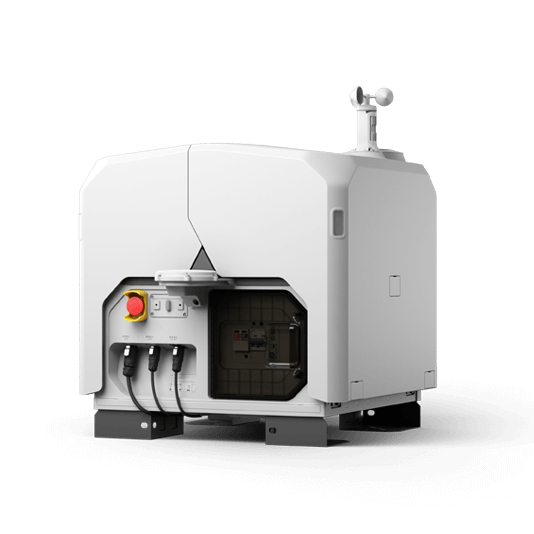

Automated Solar Farm Inspection

The DJI Dock 3 enables you to automate recurring inspection tasks with ease. Schedule an inspection task, and the DJI Dock 3 will automatically collect the data and upload the findings to the DJI FlightHub 2 cloud platform for comprehensive analysis and processing.

The device is lightweight and portable, facilitating easy installation.

Suitable for full project cycle applications, ranging from construction management to inspection tasks.

Boasts an IP56 rating, making it resilient in harsh environments.

An operating radius of 10 km enables extensive coverage of large solar farm areas.

The cloud API facilitates the transfer of collected data to third-party software.

Drone Platform

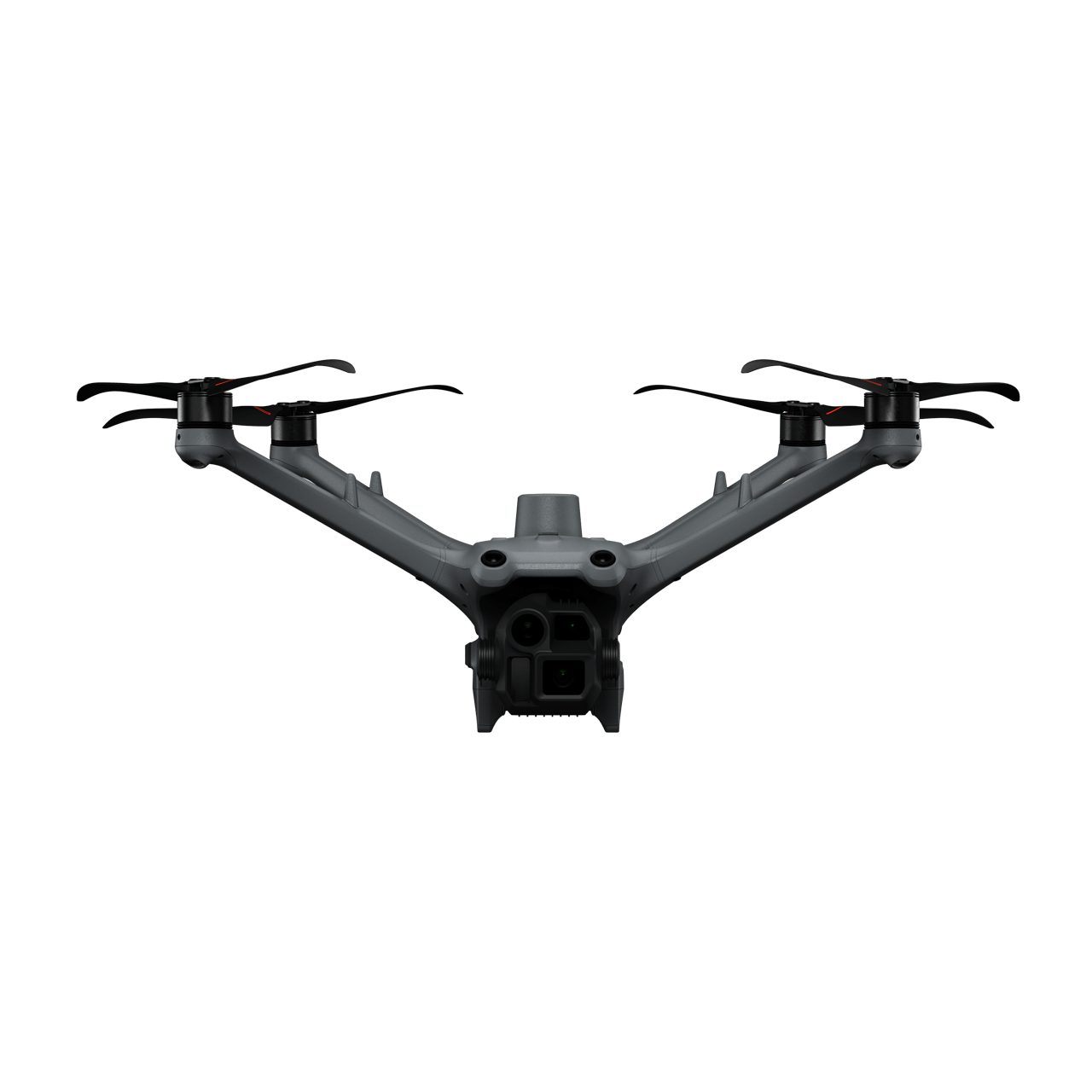

DJI Matrice 4D

... Open

Weight: 1850 g

Max Flight Time: 54 minutes

Environment Adaptability: IP55 rating, max takeoff altitude 6500 m, max wind speed resistance 12 m/s

Sensing System: Omnidirectional binocular vision system, supplemented with a 3D infrared sensor at the bottom of the aircraft

Mechanical Shutter Speed: 2-1/2000 s, minimum photo interval 0.5 s

Wide-Angle Camera: 4/3-inch CMOS, 20MP effective pixels

Medium Tele Camera: 1/1.3-inch CMOS, 48MP effective pixels

Telephoto Camera: 1/1.5-inch CMOS, 48MP effective pixels

Laser Rangefinding: 1800m measurement range (1 Hz) @20% reflectivity target

Max Flight Time: 54 minutes

Environment Adaptability: IP55 rating, max takeoff altitude 6500 m, max wind speed resistance 12 m/s

Sensing System: Omnidirectional binocular vision system, supplemented with a 3D infrared sensor at the bottom of the aircraft

Mechanical Shutter Speed: 2-1/2000 s, minimum photo interval 0.5 s

Wide-Angle Camera: 4/3-inch CMOS, 20MP effective pixels

Medium Tele Camera: 1/1.3-inch CMOS, 48MP effective pixels

Telephoto Camera: 1/1.5-inch CMOS, 48MP effective pixels

Laser Rangefinding: 1800m measurement range (1 Hz) @20% reflectivity target

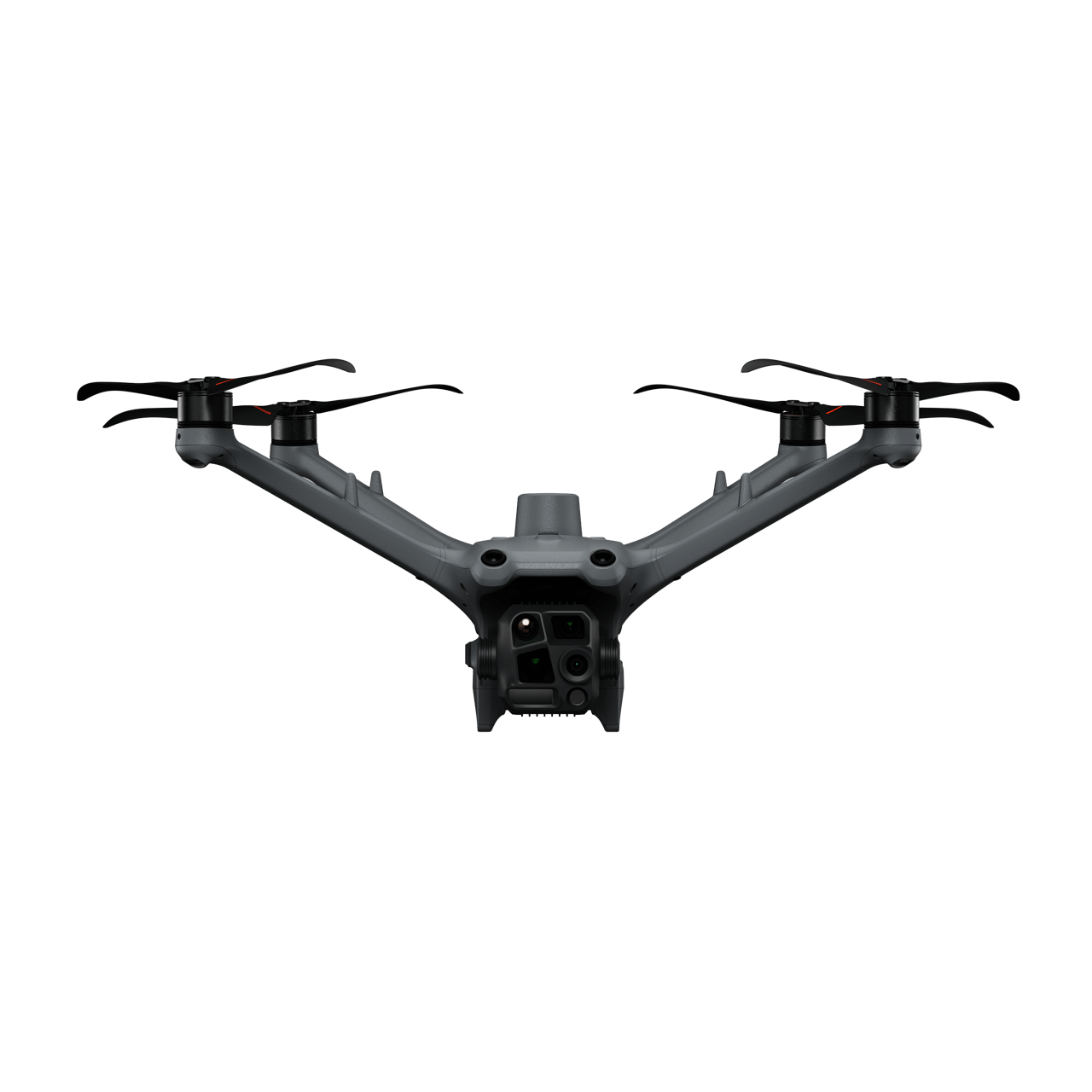

DJI Matrice 4TD

... Open

Weight: 1850 g

Max Flight Time: 54 minutes

Environment Adaptability: IP55 rating, max takeoff altitude 6500 m, max wind speed resistance 12 m/s

Sensing System: Omnidirectional binocular vision system, supplemented with a 3D infrared sensor at the bottom of the aircraft

Wide-Angle Camera: 1/1.3-inch CMOS, 48MP effective pixels

Medium Tele Camera: 1/1.3-inch CMOS, 48MP effective pixels

Telephoto Camera: 1/1.5-inch CMOS, 48MP effective pixels

Infrared Thermal Camera: 1280 × 1024@30fps (UHR Infrared Image function enabled, Night Scene mode not enabled)

Laser Rangefinding: 1800m measurement range (1 Hz) @20% reflectivity target

Max Flight Time: 54 minutes

Environment Adaptability: IP55 rating, max takeoff altitude 6500 m, max wind speed resistance 12 m/s

Sensing System: Omnidirectional binocular vision system, supplemented with a 3D infrared sensor at the bottom of the aircraft

Wide-Angle Camera: 1/1.3-inch CMOS, 48MP effective pixels

Medium Tele Camera: 1/1.3-inch CMOS, 48MP effective pixels

Telephoto Camera: 1/1.5-inch CMOS, 48MP effective pixels

Infrared Thermal Camera: 1280 × 1024@30fps (UHR Infrared Image function enabled, Night Scene mode not enabled)

Laser Rangefinding: 1800m measurement range (1 Hz) @20% reflectivity target

DJI Dock 3

... Open

Weight: 55 kg (without the drone)

Size: 1760×745×485 mm (L×W×H, dock cover opened)

Environment Adaptability: -30° to 50° C (-22° to 122° F) operating temperature, IP56 rating, maximum operating altitude 4500 m

Max Operating Radius: 10 km

Charging Time: 27 minutes

Security Camera (Internal) Resolution: 1920×1080

Size: 1760×745×485 mm (L×W×H, dock cover opened)

Environment Adaptability: -30° to 50° C (-22° to 122° F) operating temperature, IP56 rating, maximum operating altitude 4500 m

Max Operating Radius: 10 km

Charging Time: 27 minutes

Security Camera (Internal) Resolution: 1920×1080

Payload And Software

Workflow

- Mission Planning:

- Use DJI FlightHub 2 to plan inspection flight routes based on high-definition 3D model of the solar farm. - Data Collection:

- Using DJI FlightHub 2, select the preferred dock and scheduled inspection mission.

- The Matrice 4TD will execute the inspection tasks according to the plan, and uploads the captured data to DJI FlightHub 2. - Data Analysis:

- Analyze the images to detect faulty elements or required maintenance work by using the DJI Thermal Analysis Tool. Transfer the collected data to a third-party software to use automated detection algorithms.

High Performance Inspection

The DJI Matrice 30 Series delivers a potent combination of portability and performance, boasting an extended flight range of up to 15 km and ingress protection to endure severe weather conditions. It enables precise detection of solar panel defects, sediment buildup, or damage through its high-resolution visual and thermal (M30T) sensors. The series also supports dual-control operations and incorporates intelligent inspection capabilities.

The drone's foldable and compact design ensures easy transportation.

Achieves rapid deployment, operational within just 2 minutes.

Offers an extended transmission range of up to 15 km.

Provides cost-effective solutions with an integrated infrared camera.

Equipped with a laser rangefinder to accurately locate and provide coordinates for defective components within solar farms.

Drone Platform

Matrice 30 Series

... Open

Weight (incl. two batteries): 3770 ± 10 g.

Max Flight Time: 41 min.

Sensing system: Six-directional sensing and positioning.

Environment Adaptability: Max Service Ceiling Above Sea Level (without other payload) 7,000 m (with 1676 propellers); Max Wind Resistance 12 m/s.

Zoom camera: 1/2-inch CMOS, Effective pixels: 48MP.

Max Flight Time: 41 min.

Sensing system: Six-directional sensing and positioning.

Environment Adaptability: Max Service Ceiling Above Sea Level (without other payload) 7,000 m (with 1676 propellers); Max Wind Resistance 12 m/s.

Zoom camera: 1/2-inch CMOS, Effective pixels: 48MP.

Payload And Software

DJI Pilot 2

... Open

Ground control

DJI Thermal Analysis Tool 3

... Open

By identifying the temperature information of critical areas of the target, the software can be used to analyze objects across many industrial applications.

Third-Party Software

Workflow

- Mission Planning:

- Plan the drone flight routes throughout the solar farm or the area to be inspected using the DJI Pilot 2 app. - Data Collection:

- Upon arrival at the takeoff point, deploy the drone and initiate the previously saved inspection mission. The drone will automatically follow the flight route. - Data Analysis:

- Analyze the images to identify faulty elements or required maintenance work by using the DJI Thermal Analysis Tool. Transfer the data to a third-party software to identify faults using automated dectection algorithms.

Portable Thermal Inspection Solution

The DJI Matrice 4T, a compact and portable drone, comes equipped with high-performance visible and thermal imaging cameras, making it ideal for comprehensive solar panel inspections in both industrial and residential settings.

Compact and lightweight, facilitating easy transportation and handling.

Features both visual and infrared imaging cameras for enhanced inspections.

Supports fully automated and sophisticated inspection routes, allowing the drone to systematically capture data along a predefined path.

Drone Platform

DJI Matrice 4T

... Open

Weight: 1219 g (with propellers)

Max Flight Time (without wind): 49 minutes

Environment Adaptability: Max takeoff altitude 6000 m, max wind speed resistance 12 m/s

Sensing System: Omnidirectional binocular vision system, supplemented with a 3D infrared sensor at the bottom of the aircraft

Wide-Angle Camera: 1/1.3-inch CMOS, 48MP effective pixels (Matrice 4T)

Medium Tele Camera: 1/1.3-inch CMOS, 48MP effective pixels

Telephoto Camera: 1/1.5-inch CMOS, 48MP effective pixels

Infrared Thermal Camera: 1280 × 1024@30fps (Super Resolution enabled, Night Mode not activated)

Laser Rangefinding: 1800m measurement range (1 Hz) @20% reflectivity target

Max Flight Time (without wind): 49 minutes

Environment Adaptability: Max takeoff altitude 6000 m, max wind speed resistance 12 m/s

Sensing System: Omnidirectional binocular vision system, supplemented with a 3D infrared sensor at the bottom of the aircraft

Wide-Angle Camera: 1/1.3-inch CMOS, 48MP effective pixels (Matrice 4T)

Medium Tele Camera: 1/1.3-inch CMOS, 48MP effective pixels

Telephoto Camera: 1/1.5-inch CMOS, 48MP effective pixels

Infrared Thermal Camera: 1280 × 1024@30fps (Super Resolution enabled, Night Mode not activated)

Laser Rangefinding: 1800m measurement range (1 Hz) @20% reflectivity target

Payload And Software

DJI Pilot 2

... Open

Ground control

DJI Thermal Analysis Tool 3

... Open

By identifying the temperature information of critical areas of the target, the software can be used to analyze objects across many industrial applications.

Third-Party Software

Workflow

- Mission Planning:

- Plan the drone flight routes throughout the solar farm or the area to be inspected using the DJI Pilot 2 app. - Data Collection:

- Upon arrival at the takeoff point, deploy the drone and initiate the previously saved inspection mission. The drone will automatically follow the flight route. - Data Analysis:

- Analyze the images to identify faulty elements or required maintenance work by using the DJI Thermal Analysis Tool. Transfer the data to a third-party software to identify faults using automated dectection algorithms.

Multipurpose Drone Inspection

The DJI Matrice 400 is a versatile platform with interchangeable payloads tailored to meet the specific needs of each task. Whether it's mapping or inspection, the Matrice 400 provides comprehensive operational capabilities for large-scale solar farms at various project stages.

With its array of payloads, the drone delivers operational efficiency and superior inspection capabilities.

The H30T's advanced thermal sensor (1280 × 1024) elevates inspection efficiency and quality.

A faster shutter speed leads to reduced inspection durations and expanded coverage.

Dual-Control feature to enhance reliability and ensure operational safety.

Drone Platform

DJI Matrice 400

... Open

Weight: 9740±40 g (with batteries)

Max Takeoff Weight: 15.8 kg

Max Payload: 6 kg

Max Flight Time: 59 minutes

Max Horizontal Speed: 25 m/s

Sensing System: Omnidirectional binocular vision system (surround view provided by full-color fisheye vision sensors), horizontal rotating LiDAR, upper LiDAR, downward 3D infrared range sensor, and six-direction mmWave radar

Environment Adaptability: IP55 rating, max takeoff altitude 7000 m, operating temperature -20° to 50° C (-4° to 122° F)

Compatible with the Zenmuse H30 Series, Zenmuse L2, Zenmuse P1, Zenmuse V1, Zenmuse S1, and third-party payloads.

Max Takeoff Weight: 15.8 kg

Max Payload: 6 kg

Max Flight Time: 59 minutes

Max Horizontal Speed: 25 m/s

Sensing System: Omnidirectional binocular vision system (surround view provided by full-color fisheye vision sensors), horizontal rotating LiDAR, upper LiDAR, downward 3D infrared range sensor, and six-direction mmWave radar

Environment Adaptability: IP55 rating, max takeoff altitude 7000 m, operating temperature -20° to 50° C (-4° to 122° F)

Compatible with the Zenmuse H30 Series, Zenmuse L2, Zenmuse P1, Zenmuse V1, Zenmuse S1, and third-party payloads.

Payload And Software

Zenmuse H30T

... Open

Wide-Angle RGB Camera: 1/1.3-inch CMOS, 48MP effective pixels

Zoom RGB Camera: 1/1.8-inch CMOS, 40MP effective pixels, 34× hybrid optical zoom

Infrared Thermal Camera: 1280×1024@30fps

NIR Auxiliary Light Illumination Range: Approx. 8m diameter circle@100 m

Laser Range Finder: Max measurement range 3000 m

Zoom RGB Camera: 1/1.8-inch CMOS, 40MP effective pixels, 34× hybrid optical zoom

Infrared Thermal Camera: 1280×1024@30fps

NIR Auxiliary Light Illumination Range: Approx. 8m diameter circle@100 m

Laser Range Finder: Max measurement range 3000 m

Zenmuse L2

... Open

Integrates frame LiDAR, a self-developed high-accuracy IMU system, and a 4/3 CMOS RGB mapping camera.

2.5 km2 covered in a single flight.

Detection Range 250m @10% reflectivity, 100klx.

Effective Point Cloud Rate: 240,000 pts/s.

Supports 5 Returns.

Turnkey Solution.

2.5 km2 covered in a single flight.

Detection Range 250m @10% reflectivity, 100klx.

Effective Point Cloud Rate: 240,000 pts/s.

Supports 5 Returns.

Turnkey Solution.

Workflow

- Thermal Inspection Mission:

- Using the Matrice 400 equipped with the Zenmuse H30T payload, manually fly to capture thermal readings of the key components of the solar farm. Use the Live Mission Recording feature to easily repeat the same missions in the future. - Data Analysis:

- Analyze the inspection photos manually or use model detection to identify defects in the transmission corridor.