Powerline Inspection

Transmission and Distribution inspections are crucial for preventing power losses and line failures. Automated drone flights can perform daily inspections of transmission lines, allowing for early identification of defects. With thermal cameras, these drones can detect abnormal high temperatures in equipment such as wire clamps and knife switches, enabling timely fault detection and the prevention of system failures.

Painpoints

Advantages

Traditional inspection methods are costly and time-consuming due to the distance of transmission lines.

Extend operating range, frequency, and efficiency with long-distance and automated drone inspections.

The complexity of the infrastructure, with numerous inspection points, results in a high manual inspection workload and difficulties in ensuring consistent quality.

Enhance inspection quality with close-range, accurate, and repeatable data capture processes.

Maintaining inspection records is difficult, as manual inspections cannot be easily digitized, archived, or traced.

Easily store and manage drone imagery and digital models to monitor changes and prevent failures.

Environmental factors can render some areas inaccessible or hazardous, posing risks to inspection personnel.

Ensure personnel safety while maintaining high inspection quality using aerial visual and thermal imagery of critical components.

Solution

Reliable Transmision Line Inspection

Multipurpose Drone Inspection

Portable Distribution Networks Inspection

Automated Routine Inspection

Reliable Transmision Line Inspection

The DJI Matrice 30 Series delivers portable yet powerful performance, capable of handling challenging conditions. This solution enables inspection professionals to capture high-quality visual and thermal (M30T) images for precise defect identification. Plan inspection tasks using the DJI Pilot 2

app's waypoint flight mission feature, allowing for repeatable missions that increase efficiency.

This solution is compatible with the DJI Cellular module[1] for 4G-enhanced image transmission, extending its effective operating range in complex urban or mountainous environments.

app's waypoint flight mission feature, allowing for repeatable missions that increase efficiency.

This solution is compatible with the DJI Cellular module[1] for 4G-enhanced image transmission, extending its effective operating range in complex urban or mountainous environments.

The drone is foldable and portable, making it easy to transport for outdoor tasks.

Quick deployment, ready for operation in under 2 minutes.

Cost-effective, featuring an integrated infrared camera that allows direct temperature measurement.

The low-light mode captures detailed images even in dimly lit environments.

Drone Platform

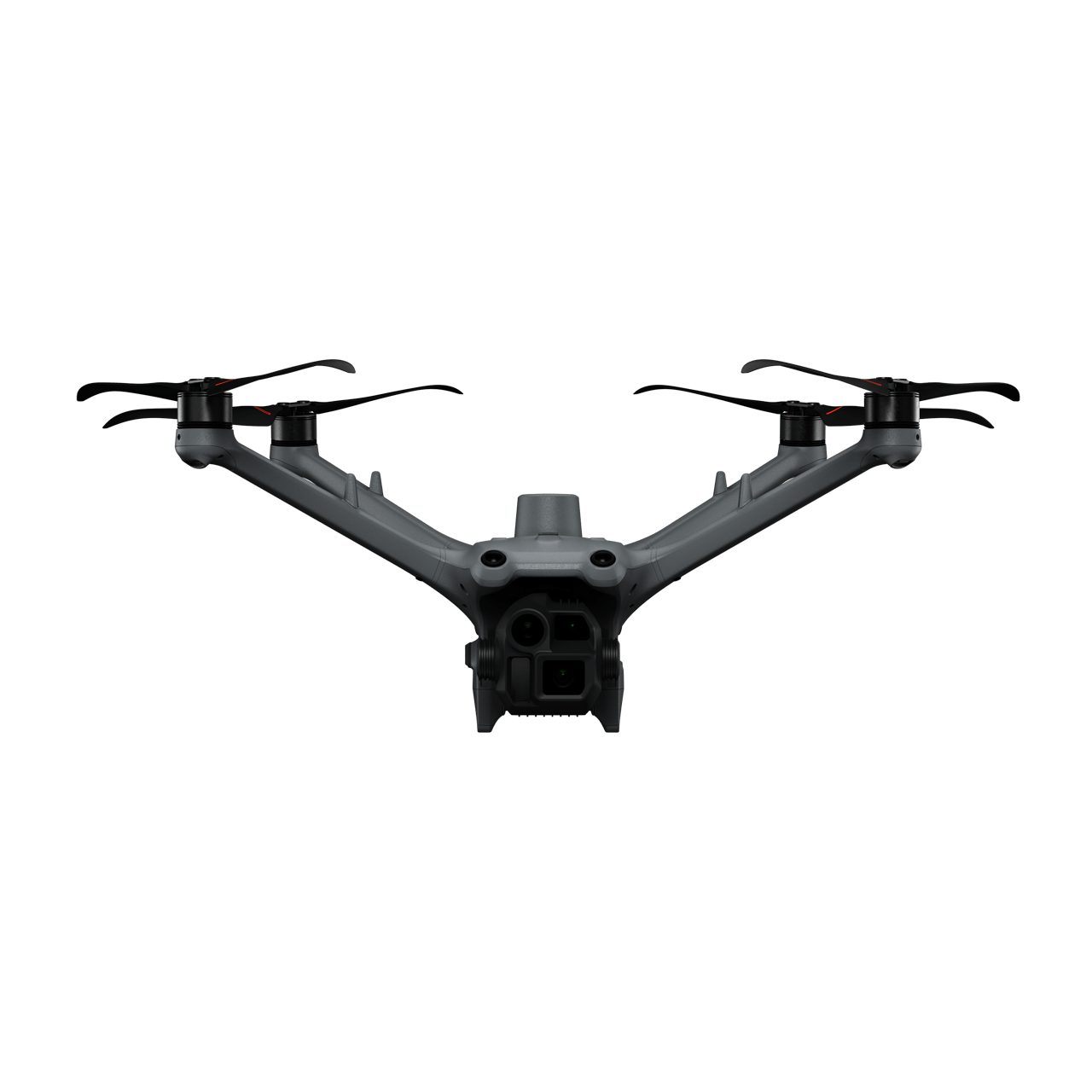

Matrice 30T

... Open

Weight (incl. two batteries): 3770 ± 10 g.

Max Flight Time: 41 min.

Sensing system: Six-directional sensing and positioning.

Environment Adaptability: Max Service Ceiling Above Sea Level (without other payload) 7,000 m (with 1676 propellers); Max Wind Resistance 12 m/s.

Zoom camera: 1/2-inch CMOS, Effective pixels: 48MP.

Max Flight Time: 41 min.

Sensing system: Six-directional sensing and positioning.

Environment Adaptability: Max Service Ceiling Above Sea Level (without other payload) 7,000 m (with 1676 propellers); Max Wind Resistance 12 m/s.

Zoom camera: 1/2-inch CMOS, Effective pixels: 48MP.

Payload And Software

DJI Pilot 2

... Open

Ground control

Workflow

- Mission Planning:

- Plan inspection route by using Waypoint Mission or fly manually while using the Live Mission Recording feature for future replicable missions. - Data Collection:

- Upon arrival at the takeoff point, quickly deploy the drone and initiate the previously saved inspection route. The drone will automatically follow the flight route. - Data Analysis:

- Analyze the inspection photos manually to identify and locate any defects.

- Integrate inspection data with existing asset management systems for further analysis, trend tracking, and maintenance planning. - Reporting and Documentation:

- Generate comprehensive inspection reports that include visual and thermal imagery, defect identification, and recommendations for corrective actions.

Multipurpose Drone Inspection

The DJI Matrice 350 RTK is a reliable platform with interchangeable payloads to meet specific task requirements. From mapping to inspection, the Matrice 350 RTK offers comprehensive operational capabilities for inspection teams.

This solution is compatible with the DJI Cellular module[1] for 4G-enhanced image transmission, extending its effective operating range in complex urban or mountainous environments.

This solution is compatible with the DJI Cellular module[1] for 4G-enhanced image transmission, extending its effective operating range in complex urban or mountainous environments.

Equipped with various payloads, it offers operational efficiency and enhanced inspection capabilities.

Longer flight time allows for extended single operations.

When paired with the Zenmuse L2, it enables high-density point cloud mapping to create accurate models of transmission lines.

When paired with the Zenmuse H30 Series, it offers high-definition zoom capability and a laser rangefinder. Combined with intelligent precise re-shooting functionality, this greatly enhances the efficiency of aerial inspections.

Drone Platform

Matrice 350 RTK

... Open

Weight: Approx. 6.47 kg(with single downward gimbal and two TB65 batteries).

Max Flight Time: 55 minutes.

Sensing system: Six-directional sensing and positioning.

Environment Adaptability: IP55, Max Service Ceiling Above Sea Level 7,000 m (with 1676 propellers,without other payload); Max Wind Resistance 12 m/s.

Max Flight Time: 55 minutes.

Sensing system: Six-directional sensing and positioning.

Environment Adaptability: IP55, Max Service Ceiling Above Sea Level 7,000 m (with 1676 propellers,without other payload); Max Wind Resistance 12 m/s.

Payload And Software

Zenmuse H30T

... Open

Wide-Angle RGB Camera: 1/1.3-inch CMOS, 48MP effective pixels

Zoom RGB Camera: 1/1.8-inch CMOS, 40MP effective pixels, 34× hybrid optical zoom

Infrared Thermal Camera: 1280×1024@30fps

NIR Auxiliary Light Illumination Range: Approx. 8m diameter circle@100 m

Laser Range Finder: Max measurement range 3000 m

Zoom RGB Camera: 1/1.8-inch CMOS, 40MP effective pixels, 34× hybrid optical zoom

Infrared Thermal Camera: 1280×1024@30fps

NIR Auxiliary Light Illumination Range: Approx. 8m diameter circle@100 m

Laser Range Finder: Max measurement range 3000 m

Zenmuse L2

... Open

Integrates frame LiDAR, a self-developed high-accuracy IMU system, and a 4/3 CMOS RGB mapping camera.

2.5 km2 covered in a single flight.

Detection Range 250m @10% reflectivity, 100klx.

Effective Point Cloud Rate: 240,000 pts/s.

Supports 5 Returns.

Turnkey Solution.

2.5 km2 covered in a single flight.

Detection Range 250m @10% reflectivity, 100klx.

Effective Point Cloud Rate: 240,000 pts/s.

Supports 5 Returns.

Turnkey Solution.

Workflow

- Powerline Modeling Mission:

- Use the Matrice 350 RTK equipped with the Zenmuse L2 and fly directly over powerline using the Powerline Follow feature. The Zenmuse L2 sensor can detect and identify power lines even in complex environments with vegetation or other obstacles.

- Once the power line is identified , the drone will then autonomously plan a flight path along the power line, maintaining a safe distance and adjusting its altitude as needed. - Model Processing:

- Import the data into DJI Terra to generate the LiDAR point cloud and plan the transmission corridor inspection route. - Inspection Mission:

- Import the route task into the Matrice 350 RTK and issue the inspection command with a single click. - Data Analysis:

- Analyze the inspection photos manually or use model detection to identify defects in the transmission corridor.

Portable Distribution Networks Inspection

The compact and portable DJI Matrice 4T, equipped with high-performance visible light and thermal imaging cameras, is ideal for comprehensive temperature inspections of distribution network equipment.

This solution is compatible with the DJI Cellular module[1] for 4G-enhanced image transmission, extending its effective operating range in complex urban or mountainous environments.

This solution is compatible with the DJI Cellular module[1] for 4G-enhanced image transmission, extending its effective operating range in complex urban or mountainous environments.

Compact and lightweight, making it easy to transport and carry.

4G-enhanced image transmission for an extended operating range.

Visual and infrared imaging cameras for enhanced inspections.

Precise positioning with the RTK module.

Drone Platform

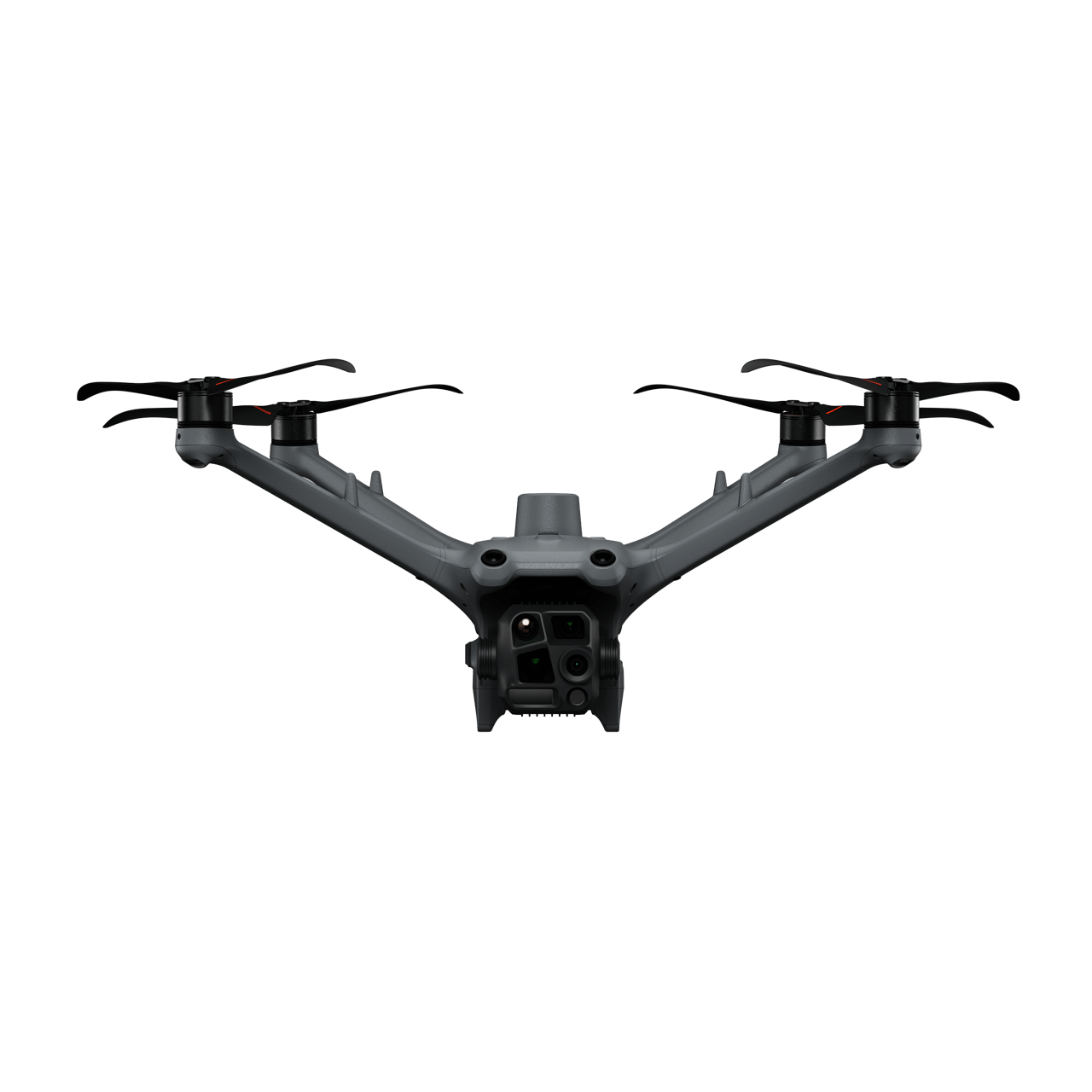

DJI Matrice 4T

... Open

Weight: 1219 g (with propellers)

Max Flight Time (without wind): 49 minutes

Environment Adaptability: Max takeoff altitude 6000 m, max wind speed resistance 12 m/s

Sensing System: Omnidirectional binocular vision system, supplemented with a 3D infrared sensor at the bottom of the aircraft

Wide-Angle Camera: 1/1.3-inch CMOS, 48MP effective pixels (Matrice 4T)

Medium Tele Camera: 1/1.3-inch CMOS, 48MP effective pixels

Telephoto Camera: 1/1.5-inch CMOS, 48MP effective pixels

Infrared Thermal Camera: 1280 × 1024@30fps (Super Resolution enabled, Night Mode not activated)

Laser Rangefinding: 1800m measurement range (1 Hz) @20% reflectivity target

Max Flight Time (without wind): 49 minutes

Environment Adaptability: Max takeoff altitude 6000 m, max wind speed resistance 12 m/s

Sensing System: Omnidirectional binocular vision system, supplemented with a 3D infrared sensor at the bottom of the aircraft

Wide-Angle Camera: 1/1.3-inch CMOS, 48MP effective pixels (Matrice 4T)

Medium Tele Camera: 1/1.3-inch CMOS, 48MP effective pixels

Telephoto Camera: 1/1.5-inch CMOS, 48MP effective pixels

Infrared Thermal Camera: 1280 × 1024@30fps (Super Resolution enabled, Night Mode not activated)

Laser Rangefinding: 1800m measurement range (1 Hz) @20% reflectivity target

Payload And Software

DJI Pilot 2

... Open

Ground control

Workflow

- Mission Planning:

- Plan inspection route by using Waypoint Mission or fly manually while using the Live Mission Recording feature for future replicable missions. - Data Collection:

- Upon arrival at the takeoff point, quickly deploy the drone and initiate the previously saved inspection route. The drone will automatedly follow the flight route. - Data Analysis:

- Analyze the inspection photos manually to identify and locate any defects. Integrate inspection data with existing asset management systems for further analysis, trend tracking, and maintenance planning. - Reporting and Documentation:

- Generate comprehensive inspection reports that include visual and thermal imagery, defect identification, and recommendations for corrective actions.

Automated Routine Inspection

DJI Dock 3 (including the DJI Matrice 4D Series) integrates with DJI FlightHub 2 to enable remote, repeatable inspections, enhancing efficiency and ensuring personnel safety. Schedule automated visual or thermal inspections, and ensure inspection quality with live streams via DJI FlightHub 2.

This solution is compatible with the DJI Cellular module[1] for 4G-enhanced image transmission, extending its effective operating range in complex urban or mountainous environments.

This solution is compatible with the DJI Cellular module[1] for 4G-enhanced image transmission, extending its effective operating range in complex urban or mountainous environments.

The drone can operate according to a pre-planned schedule and flight route, enhancing both quality and efficiency.

Remote operations reduce transportation times for pilots, improving operational costs and personnel management.

Operates in all weather conditions, day or night, adapting to various operational scenarios.

Centralized data management and analysis through DJI FlightHub 2.

Drone Platform

DJI Matrice 4D

... Open

Weight: 1850 g

Max Flight Time: 54 minutes

Environment Adaptability: IP55 rating, max takeoff altitude 6500 m, max wind speed resistance 12 m/s

Sensing System: Omnidirectional binocular vision system, supplemented with a 3D infrared sensor at the bottom of the aircraft

Mechanical Shutter Speed: 2-1/2000 s, minimum photo interval 0.5 s

Wide-Angle Camera: 4/3-inch CMOS, 20MP effective pixels

Medium Tele Camera: 1/1.3-inch CMOS, 48MP effective pixels

Telephoto Camera: 1/1.5-inch CMOS, 48MP effective pixels

Laser Rangefinding: 1800m measurement range (1 Hz) @20% reflectivity target

Max Flight Time: 54 minutes

Environment Adaptability: IP55 rating, max takeoff altitude 6500 m, max wind speed resistance 12 m/s

Sensing System: Omnidirectional binocular vision system, supplemented with a 3D infrared sensor at the bottom of the aircraft

Mechanical Shutter Speed: 2-1/2000 s, minimum photo interval 0.5 s

Wide-Angle Camera: 4/3-inch CMOS, 20MP effective pixels

Medium Tele Camera: 1/1.3-inch CMOS, 48MP effective pixels

Telephoto Camera: 1/1.5-inch CMOS, 48MP effective pixels

Laser Rangefinding: 1800m measurement range (1 Hz) @20% reflectivity target

DJI Matrice 4TD

... Open

Weight: 1850 g

Max Flight Time: 54 minutes

Environment Adaptability: IP55 rating, max takeoff altitude 6500 m, max wind speed resistance 12 m/s

Sensing System: Omnidirectional binocular vision system, supplemented with a 3D infrared sensor at the bottom of the aircraft

Wide-Angle Camera: 1/1.3-inch CMOS, 48MP effective pixels

Medium Tele Camera: 1/1.3-inch CMOS, 48MP effective pixels

Telephoto Camera: 1/1.5-inch CMOS, 48MP effective pixels

Infrared Thermal Camera: 1280 × 1024@30fps (UHR Infrared Image function enabled, Night Scene mode not enabled)

Laser Rangefinding: 1800m measurement range (1 Hz) @20% reflectivity target

Max Flight Time: 54 minutes

Environment Adaptability: IP55 rating, max takeoff altitude 6500 m, max wind speed resistance 12 m/s

Sensing System: Omnidirectional binocular vision system, supplemented with a 3D infrared sensor at the bottom of the aircraft

Wide-Angle Camera: 1/1.3-inch CMOS, 48MP effective pixels

Medium Tele Camera: 1/1.3-inch CMOS, 48MP effective pixels

Telephoto Camera: 1/1.5-inch CMOS, 48MP effective pixels

Infrared Thermal Camera: 1280 × 1024@30fps (UHR Infrared Image function enabled, Night Scene mode not enabled)

Laser Rangefinding: 1800m measurement range (1 Hz) @20% reflectivity target

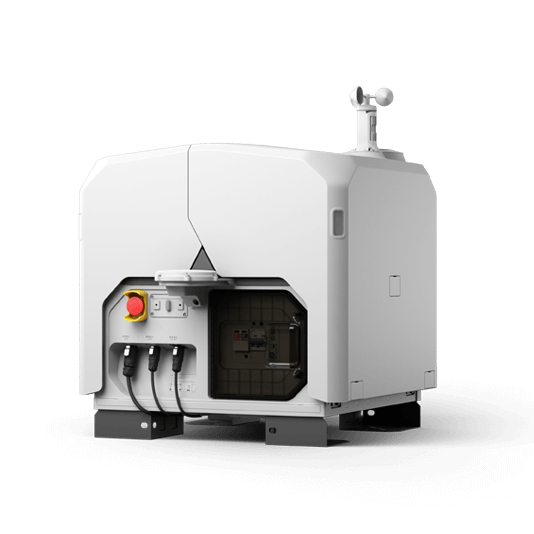

DJI Dock 3

... Open

Weight: 55 kg (without the drone)

Size: 1760×745×485 mm (L×W×H, dock cover opened)

Environment Adaptability: -30° to 50° C (-22° to 122° F) operating temperature, IP56 rating, maximum operating altitude 4500 m

Max Operating Radius: 10 km

Charging Time: 27 minutes

Security Camera (Internal) Resolution: 1920×1080

Size: 1760×745×485 mm (L×W×H, dock cover opened)

Environment Adaptability: -30° to 50° C (-22° to 122° F) operating temperature, IP56 rating, maximum operating altitude 4500 m

Max Operating Radius: 10 km

Charging Time: 27 minutes

Security Camera (Internal) Resolution: 1920×1080

Payload And Software

Workflow

- Mission Planning:

- Use DJI FlightHub 2 or preferred third-party sofware to plan inspection routes based on high-definition models of transmission lines and towers.

- Or import previously saved inspection flight routes to the DJI FlightHub 2 via the Pilot 2 app using the Live Mission Recording feature. - Data Collection:

- Using DJI FlightHub 2 select the preferred dock and scheduled inspection mission.

- The DJI Matrice 4D series drones execute inspection tasks as planned, and the captured results are automatically uploaded to the DJI FlightHub 2 cloud platform. - Data Analysis:

- Analyze the inspection photos manually or export to a third-party model detection software to identify defects or deterioration on the components.

1. This service is not available in some countries and regions. Please consult your local dealer for details.